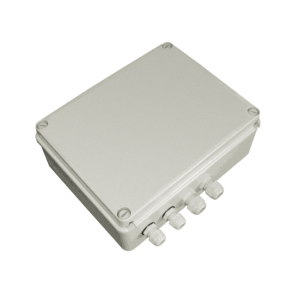

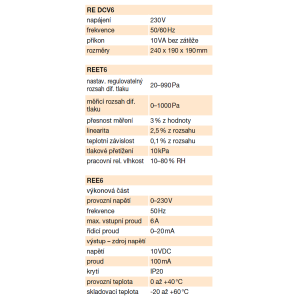

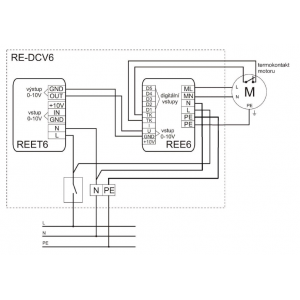

Connection of the products REET6 - flow controller and REE6 - triac controller into one switchboard with four grommets for wiring. The controllers are in standard module boxes, mounted on a DIN rail and connected with the necessary cabling. The enclosure is IP55 rated (subject to installation conditions).

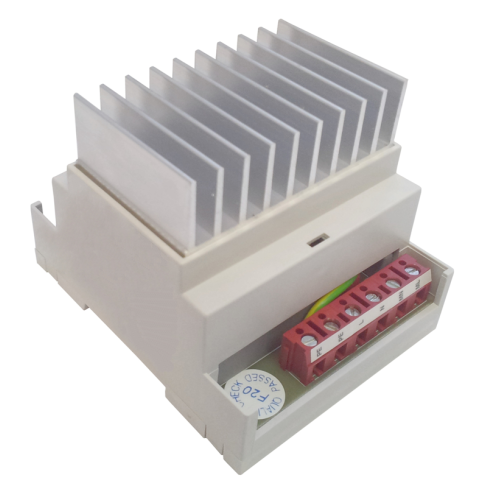

REE6 triac controller

The single-phase triac controller is used to continuously control the power or speed of the fan depending on the size of the input variable. An already connected 0-10 VDC voltage output from the REET6 can be used as the control variable, as well as a 0-20 mA current input or 5 digital inputs (stages) that are evenly distributed throughout the control range. The activation of a given digital input is by connecting e.g. a transistor with an open collector or a contact against GND on the terminal block. The controller is equipped with an emergency motor thermocontact input. To protect the thermal overload of the triac, a temperature sensor is placed inside the controller which reacts in case of overheating as well as failure of the emergency input, i.e. full closure of the triac. The cross-sections of the connecting wires must be dimensioned to take into account the length of the wiring and the risk of interference.

- power and speed control depending on the size of the input

- stepless or stepped control

- galvanically isolated control inputs

- emergency input

- thermal overload protection of the triac

- adjustable minimum speed

REET6 flow controller

The regulator is equipped with a differential pressure sensor that either senses the actual pressure or is used to measure the flow in the duct. The controller then regulates the fan output to maintain the desired pressure or flow set by the rotary element.

- constant pressure/flow control

- set the desired value by the rotary element

- analogue control output signal 0-10 V

- remote control via analogue input 0-10 V

- self-calibration of pressure differential sensors

Adherence to these instructions should not pose any safety, health or environmental risks in accordance with EC directives (CE marked). The same applies to other products used in the device or during installation. Consider the following warnings:

• Observe the safety instructions to prevent damage to the device or personal injury.

• The technical information in this manual must not be changed.

• It is forbidden to interfere with the motor of the device.

• In order for the device to comply with EC directives, the device must be connected to the mains in accordance with the applicable regulations.

• The device must be installed in such a way that under normal operating conditions it cannot come into contact with any moving part and / or live part.

• The device complies with the applicable regulations for the operation of electrical equipment.

• Always disconnect the device from the power supply before carrying out any work on it.

• Appropriate tools must be used when handling or maintaining the device.

• The device must only be used for the purposes for which it is intended.

• This appliance is not intended for use by children under 8 years of age and persons with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a responsible person. The user must ensure that children do not play with the device. Cleaning and maintenance of the appliance must not be carried out by children without supervision.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email