Information

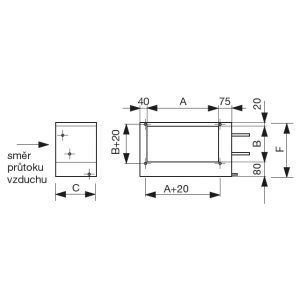

- it is designed for square ducts in connection with DIRECT AIR units

- the radiator shell is made of galvanized sheet metal

- the fins are aluminum on copper tubes

- the connection is by soldering

- the radiator contains a droplet eliminator

- usable up to an operating pressure of 30 bar (3 MPa)

Installation and operation

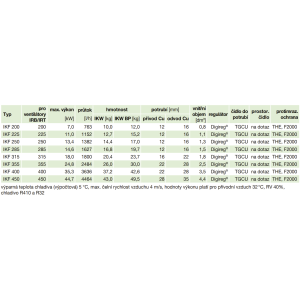

- the air velocity in the duct must not exceed 4 m/s, otherwise an additional droplet eliminator must be added after consultation with the EDV technical department

- direct coolers may only be installed indoors (on site, where the temperature is permanently above 0 ˚C

- installation exclusively in horizontal position

- an air filter must be installed in front of the cooler (protection against pollution)

- it is recommended to include the cooler behind the heater

- when installing, it is necessary to remember to drain and fill the system and to provide access for servicing

- within the design the condenser should be designed with regard to the amount of condensate

- the condensate drainage with the odour trap should be controlled for the possibility of drying out and to ensure sufficient water column height to overcome the pressure drop of the trap

- as a guide, the following can be used to determine the minimum safe level difference in the trap, by taking the total fan pressure Pt in mm of water column, this value is increased by approximately 50 % (this value represents a practical recommended value for the height of the water column in the siphon so that the odour trap cannot be overcome by overpressure blowing or vacuuming by the fan)

- the passing air must not contain solid, fibrous, sticky or aggressive impurities. It must also be free of chemical substances that cause corrosion of the materials used, i.e. corrode aluminium, copper and zinc

- to reduce pressure losses (and thus reduce operating costs) we recommend using coolers with air bypass around the evaporator (type IKFxxBP)

- the connection of the evaporator to the source is by means of insulated copper piping. The cooling capacity is controlled by switching the condensing unit (START-STOP operation)

- a suitable cooling source can be offered by consulting the technical department

Note

The condenser must be installed in a pipe route with the air flow in the direction of the arrow on the condenser cabinet, if the condenser is installed in reverse, the condensate is not drawn into the condenser and flows out of the condenser. For reliable operation of the condenser, frost protection or power control (defrost cycle) must be provided. The order must specify the requirement for right or left-hand version. The design is understood according to the direction of the outlets when viewed from the front (i.e. the evaporator fins are closer to you).

Frost protection

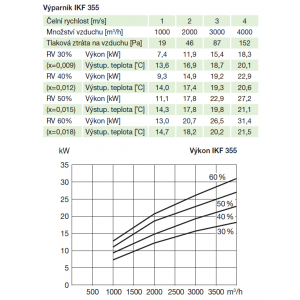

In normal use we must provide evaporator frost protection. In winter, the bypass is open, which limits the cooling of the incoming air. The frost protection is provided by a sensor so that when the temperature behind the condenser drops below +5 ˚C, the cooling source (condensing unit) is disconnected. The reconnection occurs when the temperature behind the condenser rises above +5 ˚C and there is a simultaneous cooling demand from the control system. Thermostats with a contact output can be used, e.g. the F2000 sensor, which is designed to sense the temperature of the air in the ductwork behind the evaporator. The sensor has an adjustable temperature range of -30 ...+30 ˚C, IP44 protection, contact Umax = 250 V, Imax = 16 A.

Mounting and maintenance of direct coolers - evaporators

The direct cooler must be less than the maximum permissible distance from the condensing unit. The limits for maximum supply line length and maximum elevation between the source and the evaporator must be observed. The installation must be carried out on the basis of a professional design by a qualified designer who is responsible for the correct selection of the evaporator and accessories. Installation and commissioning may only be carried out by a professional installer authorised in accordance with the generally applicable regulations. The cooling system must be carefully checked before installation. In particular, it is necessary to check that some parts are not damaged and that the piping, fins and evaporator manifolds are in order. The connecting copper piping must be insulated along its entire length, and each pipe must be insulated separately.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email