S&P SISTEMAS DE VENTILACIÓN, S.L.U.

Llevant, 4

Polígono Industrial Llevant

08150 Parets del Vallès

Barcelona – Spain

consultas[zav]solerpalau[teč]com

www.solerpalau.com/en-en/home

Product description

Cabinet

It is made of steel sheet, coated with black lacquer, the screws are electroplated.

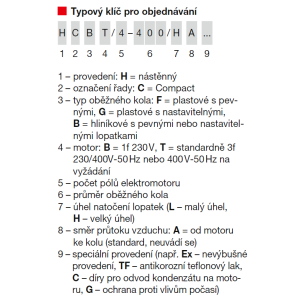

Running wheel

is made of Al alloy. The impeller is statically and dynamically balanced. The rotation of the blades is set by the manufacturer.

Motor

is asynchronous, depending on type with short armature, stator with cooling fins, lacquer finish. Motors are 3-phase for 230/400 V. The motors are with class F insulation and operating temperature -40 to +70 °C (type HCBT/4-710 H -40 to +55 °C). Grease-filled ball bearings for lifetime. IP65 protection.

Speed control

is carried out by transformer regulators by changing the voltage or by frequency converters.

Rotation direction

can be changed. With a standard impeller, the flow rate drops by approx. 30% when the direction of rotation is reversed. The air flow is standard from the motor to the impeller.

Clamps

is made of black plastic as standard. The terminal block is located on the engine.

Noise

emitted by the fan is tabulated, measurements are taken at a distance equal to three times the impeller diameter (but at least 1.5 m) in the free acoustic field.

Mounting

of the fans at each position of the motor axis.

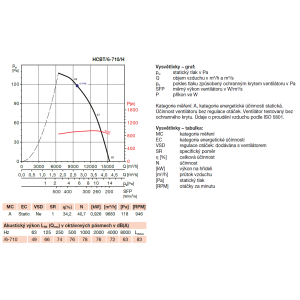

Parameters

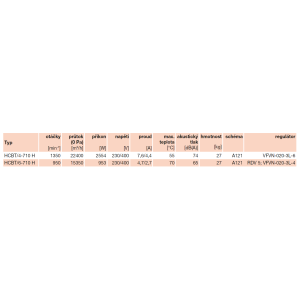

| Základní údaje | |

|---|---|

| Fan type | Axial |

| Installation | Wall |

| Weight | 27,00 kg |

| Max. air temperature | 70 °C |

| Připojení | |

| Connection pipe diameter | 710 mm |

| Elektrické parametry | |

| Power supply | 230/400 V |

| Ingress Protection | IP65 |

| Engine type | AC |

| Maximum power input | 953 W |

| Maximum current | 4,70 A - 2,70 A |

| Regulatability | Ano |

| Vybavení | |

| Check valve | No |

| Delayed run-down | No |

| Adjustable coasting | No |

| Hygrostat | No |

| Motion sensor | No |

| Adjustability | No |

| Particle filter | No |

| More intake ports | No |

| Sound insulation | No |

| Ball bearings | Yes |

| Další | |

| Maximum speed | 950 min⁻¹ |

Adherence to these instructions should not pose any safety, health or environmental risks in accordance with EC directives (CE marked). The same applies to other products used in the device or during installation. Consider the following warnings:

• Observe the safety instructions to prevent damage to the device or personal injury.

• The technical information in this manual must not be changed.

• It is forbidden to interfere with the motor of the device.

• In order for the device to comply with EC directives, the device must be connected to the mains in accordance with the applicable regulations.

• The device must be installed in such a way that under normal operating conditions it cannot come into contact with any moving part and / or live part.

• The device complies with the applicable regulations for the operation of electrical equipment.

• Always disconnect the device from the power supply before carrying out any work on it.

• Appropriate tools must be used when handling or maintaining the device.

• The device must only be used for the purposes for which it is intended.

• This appliance is not intended for use by children under 8 years of age and persons with reduced physical, sensory or mental capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction concerning use of the appliance by a responsible person. The user must ensure that children do not play with the device. Cleaning and maintenance of the appliance must not be carried out by children without supervision.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email