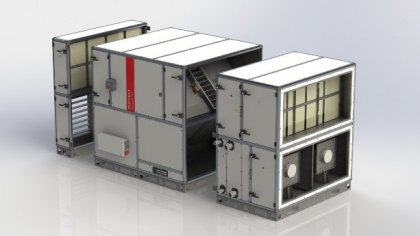

The company ELEKTRODESIGN ventilators, s.r.o. is not only a successful supplier in the range of fans and air conditioning accessories, but also in recent years a manufacturer and supplier of heat recovery units for commercial and residential use, including its own control systems. In the area of DUOVENT® commercial units, ELEKTRODESIGN ventilators, s.r.o. has prepared a new range of units from the DUOVENT® family under the name MODULAR. The MODULAR series of units is a complementary series that extends the current series of DUOVENT® COMPACT units and thus extends the range of usable air outputs up to a nominal air flow of 14500 m3/h. The usable airflow range of the MODULAR units covers the field from 7000 m3/h to 14500 m3/h. The DUOVENT® MODULAR series units are available in four performance versions and two heat recovery system versions. The DUOVENT® MODULAR DV type is equipped with a counterflow aluminium heat recovery unit and the DUOVENT® MODULAR RV type is equipped with a rotary heat recovery exchanger.

Not to be left behind is the wide range of accessories, including ROOFPACK accessories, which facilitate the use of the units in outdoor environments. Of course, the wide range of user configurations of the Digireg® control system can tailor each unit to the requirements of a specific project. The Digireg® system comes standard with a Modbus communication interface for connection to higher-level building control systems.

Figure 1: Examples of the DUOVENT® MODULAR DV/RV

The main design attributes of the units are:

- Framed EN AW 6060 T5 hardened aluminium construction with internal cavity, with the possibility of inserting additional insulation to reduce the effect of thermal bridges in the outdoor version of the units. The frame construction of the unit ensures very good rigidity of the entire unit skeleton.

- The frame structure is filled with 45 mm thick sandwich panels with insulation with non-combustible stone wool boards (reaction to fire class A1). The outer face steel sheet of the panel is galvanised and painted in RAL9002, the inner steel sheet is galvanised. On request, the units can be provided with additional surface protection based on polyester or epoxy powder coatings. The application of this superior surface protection is possible on both the exterior and all interior components of the unit.

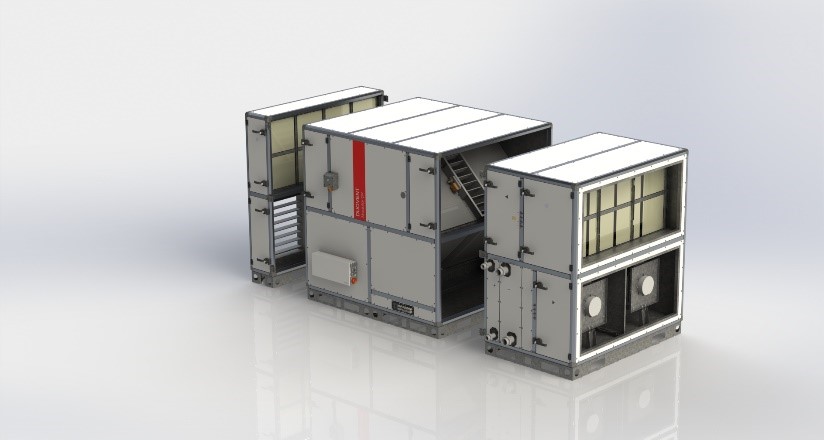

- The unit is always dispatched from the factory in 3 separate blocks, which facilitates the handling of the unit during the transport phase to its destination. All separately delivered blocks are already equipped with a complete MaR system.

Figure 2: Transport blocks for DUOVENT® MODULAR DV/RV units - The entire cladding has a heat transfer class T2 and a mechanical stability class D2 according to EN1886.

- For easier connection to the HVAC ductwork during the installation of the unit on site, the connecting sandwich panels are fitted with an integrated 30 mm high flange, which is ready for the connection of the downstream P30 size air handling flange profile.

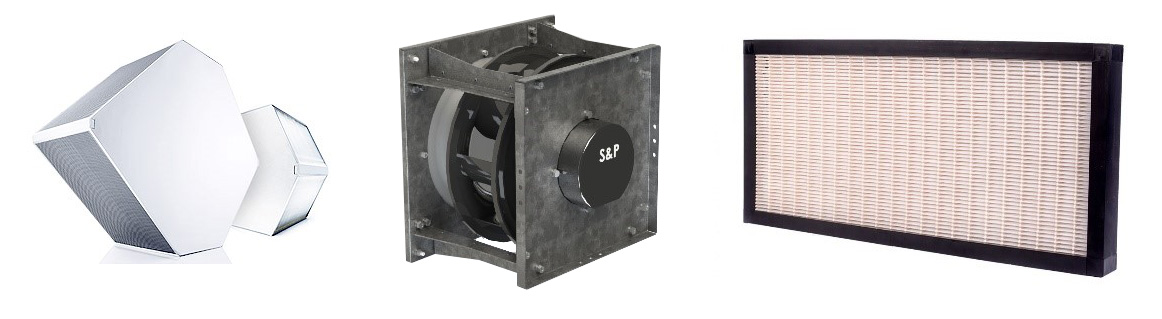

- The recuperator exchanger version DV is made of aluminium sheet with silicone-free technology with a maximum leakage of 0.2% of nominal flow at 400 Pa pressure difference between the outlet and inlet of the recuperator. The maximum recovery efficiency is up to 90%.

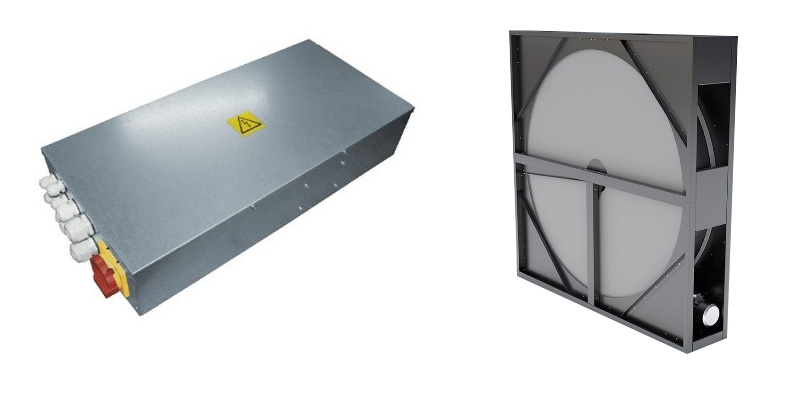

- The regenerative exchanger of the RV version is a rotary continuously variable frequency drive. The rotor is alternately wound from a flat and radlated layer of aluminium foil. The rotary exchanger is available in temperature or hygroscopic versions with a zeolite layer for additional moisture transfer. The seal between the rotor and the casing is provided by a labyrinth seal with an average leakage rate below 1,5 % of nominal air flow. Maximum regeneration efficiency is up to 85%.

- Regulation dampers are aluminium with leakage class 2 according to EN1751 equipped with Swiss BELIMO actuators.

- The fan impellers with backward curved blades are made of a special composite with temperature resistance from -20°C to +60°C, are very light and exhibit minimal vibration due to perfect static and dynamic balance.

- The EC electric motors are used to drive the fans, which are directly mounted on the impeller and mounted on galvanized steel frames in the unit. The frames are connected to the supporting parts of the unit via vibration isolators. The EC motors can be equipped with add-on modules that allow the fans to be diagnosed using a mobile app via Bluetooth wireless communication.

- Compact filter elements are available in filtration classes from ISO Coarse 80% to ISO ePM1 90% with low pressure drop polypropylene filter material or standard synthetic fiber material. Upon customer request, the unit can be retrofitted with two-stage filtration on both the inlet and outlet of the unit with the option of installing a grease filter element.

- The water heaters, water coolers and direct evaporators are made of copper tubes on which aluminium fins are strung with an openwork profile increasing the efficiency of heat transfer from the fins to the ambient air. Direct evaporators are supplied for all currently used refrigerants R410A, R32. Direct evaporators are optimized during production for use with a specific type of condensing unit or heat pump.

- Electric heaters of our own manufacture have heating rods made of stainless steel smooth tubes, which house the heating cables themselves and are equipped with an emergency and operational safety thermostat. Due to the custom design of the electric heaters, atypical designs of electric heaters with different power requirements and different number of heating sections can be manufactured upon customer request.

- The integrated Digireg® custom measurement and control system lends the units a multitude of control options with the ability to be customized to meet the requirements of each project. As standard, the units are supplied with a variable air volume (VAV) control option that allows the user to adjust the air flow rate from 0-100% of nominal flow. Optional COP (constant operating presure) or CAV (constant air volume) control is available. The COP control option allows the unit to maintain a constant overpressure or underpressure in the supply and discharge ducts. The CAV option allows the unit to maintain a constant air flow rate regardless of changes in ductwork pressure losses or changes in internal unit pressure losses (e.g. filter fouling). Another option is automatic airflow control from an external CO2, RH or VOC sensor.

Figs. 3, 4, 5: Counterflow recuperator; Fan with EC motor; Compact filter

Fig. 6, 7: Digireg control system switchboard in IP20; Rotary regenerative heat exchanger

The DUOVENT® Modular DV/RV units comply with the EU Ecodesign Directive Regulation No. EC/1253/2014 in the following range of nominal flow rates for each size. The unit can also be supplied in a process version where the unit does not comply with the Ecodesign Directive. The process version of the DUOVENT® Modular DV/RV units can be used for applications that do not fall under the Ecodesign Directive up to an air flow rate of 16,000 m3/h.

| Unit size | Vnom (m3/h) |

| DV 8500 | 8500 |

| DV 10100 | 10100 |

| DV 12000 | 12000 |

| DV 14500 | 14500 |

| RV 8500 | 7800 |

| RV 10100 | 9300 |

| RV 12000 | 11500 |

| RV 14500 | 13600 |

Shipped from the factory with the MaR Digireg control system installed, the unit provides the convenience of controlling all available functions of the unit via a color touch screen. For service purposes, the system can be fully configured in the service menu or by using the service software available to ELEKTRODESIGN ventilators, Ltd. service technicians. The unit is factory fitted with temperature and pressure sensors, damper actuators and is connected to the control system according to the technological schemes of the measurement and control system, has a switchboard located on the side of the unit and contains the controller itself and all safety elements including the service switch. The switchgear is supplied in IP20 protection as standard for the indoor version and IP65 protection for the outdoor version.

Figure 8: Example of the wiring of DUOVENT® MODULAR

To facilitate diagnosis of operating conditions and unit adjustment, the new units are equipped with pressure probes on the outside of the cladding to connect differential pressure measuring instruments to determine the specific supply or exhaust fan airflow. In addition, water heater freeze protection has been improved. A capillary antifreeze thermostat is installed in the units along with a return water sensor.

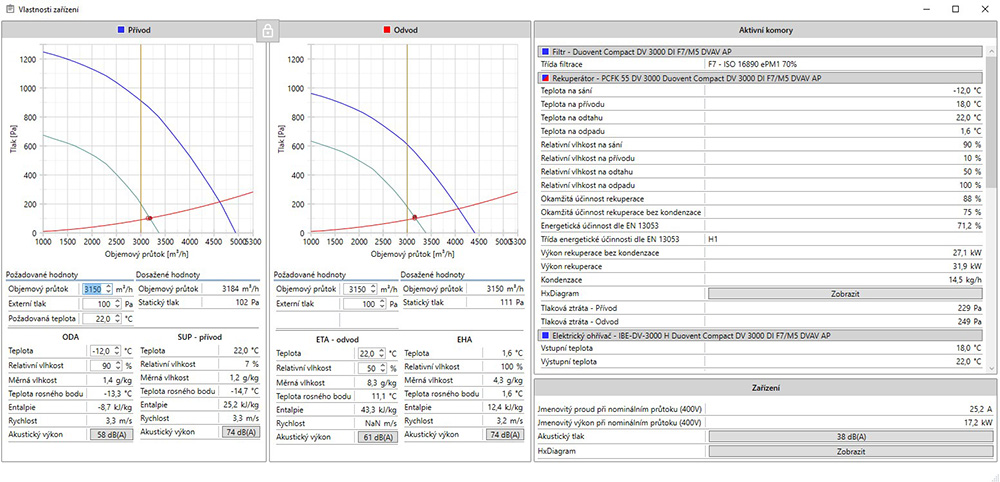

For easy selection of DUOVENT® MODULAR units, including assignment of the control system, the VentiCAD design software is used, which mainly serves the purpose of easy design of heat recovery units from the standard portfolio of ELEKTRODESIGN ventilators, s.r.o. Like any selection program, it aims to facilitate the work of designers and technical staff in the preparation of design and technical documentation of HVAC systems for commercial buildings.

Fig. 9: Preview of the user interface of the VentiCAD selection program

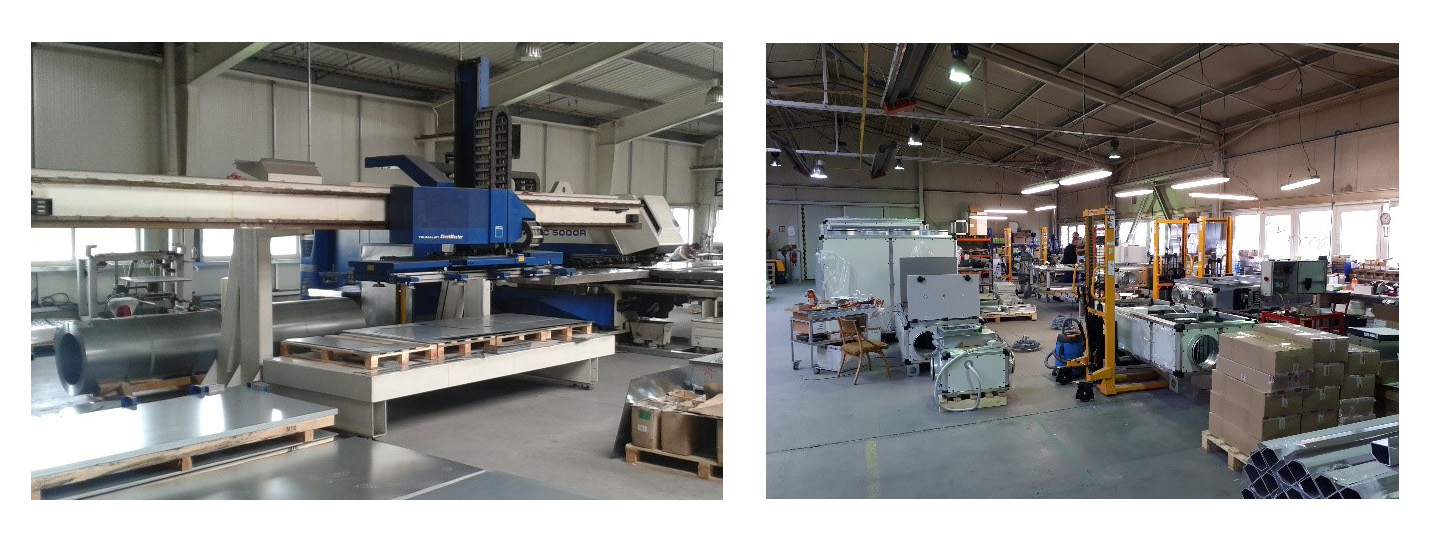

The assembly and production of DUOVENT® MODULAR units is carried out in the Czech Republic in a modern assembly plant that fully complies with the concern standards of the parent company Soler & Palau. Each manufactured DUOVENT® unit is subjected to a two-stage output quality control and is subjected to an initial setup of the Digireg control system, called SETpack (SETpack = setup of unit parameters according to the specific application used in the project). After the units are installed on site, each manufactured unit is subjected to a further stage of checking and setting called STARTpack, which is carried out by an authorised service technician of ELEKTRODESIGN ventilators, s.r.o. on site. During the STARTpack, the service technician checks the connection of the unit to all HVAC, electrical, or heating water and cooling distribution systems, checks the basic parameters of the unit (air flow, external pressure, total current drawn, etc.) and adjusts the parameters of the Digireg control system. The STARTpack service also includes training of the HVAC unit operator.

Figure 10: Production area of ELEKTRODESIGN ventilators, s.r.o.

Fig. 11: Installation of DUOVENT® MODULAR units in the production plant of ELEKTRODESIGN ventilators, s.r.o.

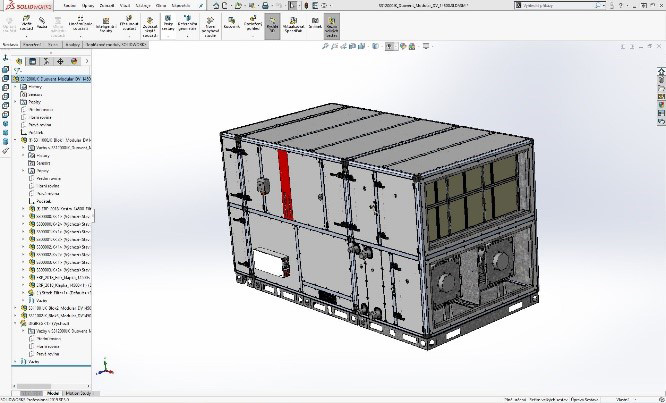

All DUOVENT® MODULAR units are designed in Solidworks 3D modeler during the production preparation phase, which guarantees higher quality and accuracy of production. During the assembly of DUOVENT® MODULAR units, advanced production quality control methods are used. The production of the unit parts is carried out on the TruPunch 5000 and 2000 advanced punching presses, while the subsequent production of sheet metal parts is carried out on the TruBend 3100 bending presses.

Figure 12: DUOVENT® MODULAR unit design in Solidworks 3D modeler