The ground air exchanger significantly increases the efficiency and effectiveness of ventilation systems with heat recovery - without energy consumption requirements.

Benefits

- additional air preheating without energy requirements during cold periods of the year (additional air heating is required at extremely low outdoor temperatures)

- prevents the heat recovery unit from freezing

- pleasant cooling during warm days

- ED Geoflex is a set of mutually matched components

Features

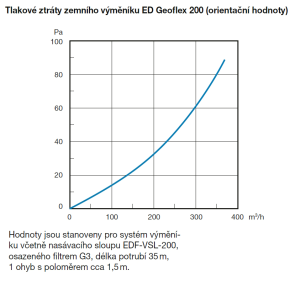

The ground air exchanger takes advantage of the relatively constant soil temperature of approximately 8 to 12 ºC at a depth of 1.8 m (min. 1.2 m) in the ground. As the depth increases, the temperature in the ground increases and approaches a constant value throughout the year.

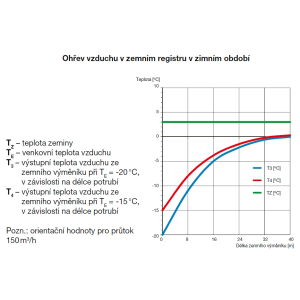

In the cold season, with outside temperatures below 0ºC, it preheats the intake air by up to 14 K. This ensures that the intake air reaches a temperature above 0 ºC before entering the recovery unit, which guarantees operation without the risk of the recuperator freezing and a positive impact on the energy balance, i.e. higher balance efficiency.

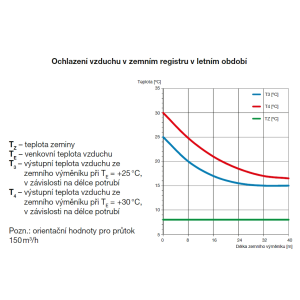

In the warm season at outdoor temperatures above +22 ºC, the air exchanger cools the intake air and thus significantly reduces the indoor air temperature.

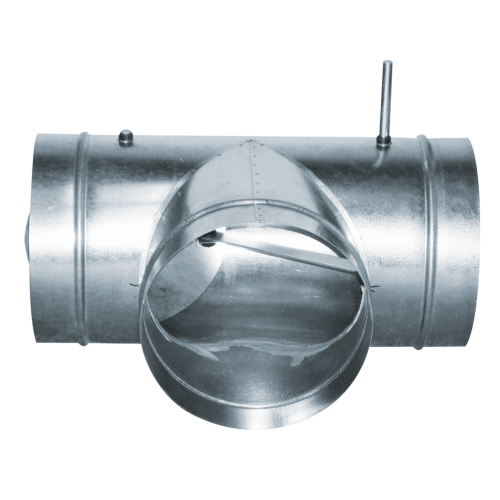

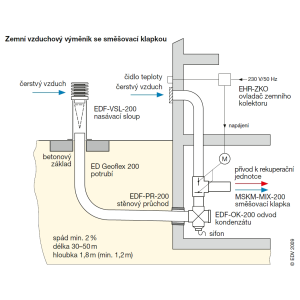

In the transitional period when outdoor temperatures are between 0 ºC and +22 ºC, air is drawn outside the air exchanger tube directly from the outside (through the perimeter wall). The suction is switched automatically depending on the outside temperature (outside temperature sensor that controls the electric switching damper). The outside air therefore enters the heat recovery unit energy-optimised, saving energy and achieving a more comfortable indoor climate.

Design principles

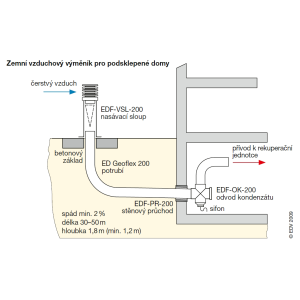

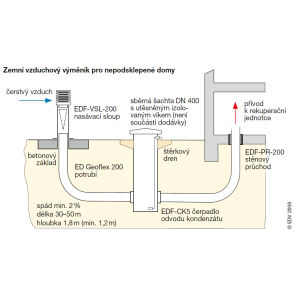

- In order to ensure the highest possible heat transfer, the ground heat exchanger piping should be laid to a depth of 1.8 m (min. 1.2 m) for a total length of 30-45 m, while maintaining a min. pipe gradient of 2% for condensate drainage to a cross piece with a siphon or alternatively a cross piece with a siphon. The piping can also be laid in two parallel branches with a length of 15 to 20 m with their connection in the collection shaft)

- The above mentioned layout and length design meet the important principle that the air temperature from the heat exchanger does not fall below 0 ºC in winter. This ensures that no condensate freezing occurs in the heat exchanger of the ventilation unit

- Because of possible freezing around the pipe of the ground heat exchanger in winter, it is necessary to avoid crossing with the water pipe (minimum crossing distance is 1 m). The min. distance when running parallel to the house wall is again 1 m

- The amount of condensate formed can be determined by calculation (using a Mollier diagram). An approximate value for the summer period at a temperature of +32 ºC with a relative humidity of 40% is approx. 0.17 l of condensate per hour

- The intake section with the pre-set filter should be located in a place with drier air (i.e. not near water bodies, wet habitat, etc.), in a place accessible for inspection and filter replacement. The intake should not be installed in an area where odours are generated (compost, etc.)

- When laying the pipe, care should be taken to ensure the best possible efficiency of heat transfer between the pipe and the soil, i.e. in no case should the pipe be filled with sand or gravel, but use soil (clay, compacted soil) that is as firm and compacted as possible

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email