Information

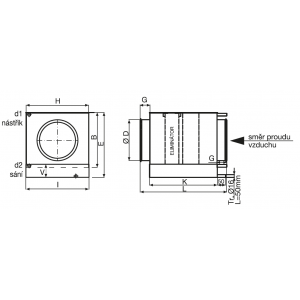

- it is designed for circular piping

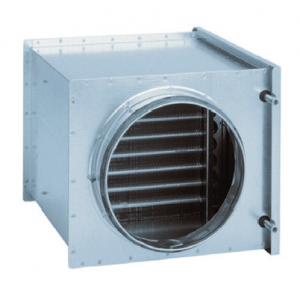

- the radiator shell is made of galvanized sheet metal

- the condensate drain pan is aluminum

- the fins are aluminum on copper tubing

- the connection is a threaded clamp transition, not included in the delivery or by soldering (see table)

- designed for R410a refrigerant

- maximum working pressure is 40 bar

Installation and operation

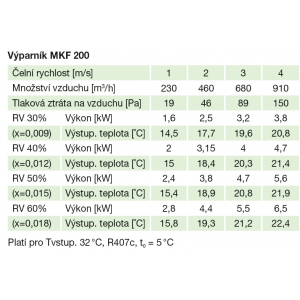

- recommended front air velocity for MKF with integrated droplet eliminator is up to 4 m/s, for air velocity calculation the evaporator flow area is considered, higher speeds should be consulted with the EDV technical department

- installation in horizontal position only

- an air filter must be installed in front of the condenser (protection against contamination)

- it is recommended to place the condenser behind the heater

- when installing the condenser, it is necessary to remember to drain and fill the system and to provide access for servicing

- in the design, the condenser should be designed to take into account the amount of condensate

- the condensate drainage with the odour trap should be controlled for the possibility of drying out and to ensure sufficient water column height to overcome the pressure drop of the trap

- to establish the minimum safe level difference in the trap, the following can be used as a guide, by taking the total fan pressure Pt in mm of water column, this value is increased by approximately 50 % (this value represents a practical recommended value for the height of the water column in the siphon so that the odour trap cannot be overcome by overpressure blowing or vacuuming by the fan)

- the passing air must not contain solid, fibrous, sticky or aggressive impurities. It must also be free of chemicals that cause corrosion of the materials used, i.e., erode aluminum, copper and zinc

- a suitable cooling source may be offered in consultation with the engineering department

NOTICE

The cooler must be installed in a duct route with air flow in the direction of the arrow on the cooler housing. If the condenser is installed backwards, condensate is not drawn into the condenser and flows out of the condenser. For reliable operation of the condenser, frost protection or power control (defrost cycle) must be provided. In the order it is necessary to specify the requirement for the right or left version.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email