Cabinet

It is made of galvanized steel sheet coated with black lacquer, screws are electroplated.

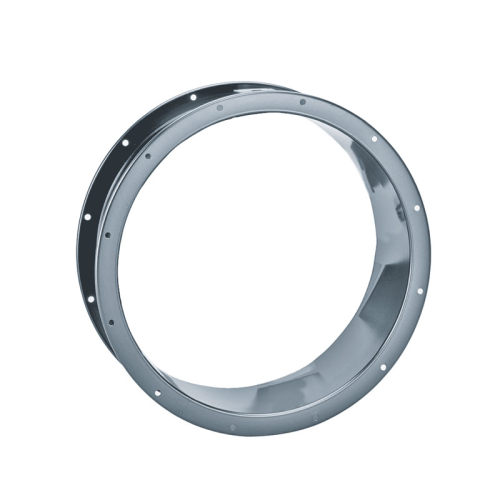

Running wheel

is made of sheet steel up to Ø 355, higher diameters have Al alloy blades, the "SICKLE" shape is specially optimised for maximum flow and pressure with minimum noise. The impeller is pressed directly onto the motor.

Motor

is asynchronous with short armature, external rotor and start-up capacitor. Class F insulation, IP54 protection. Grease-filled ball bearings for lifetime. Motor is dynamically balanced to ISO 1940.

Speed control

is performed by a frequency converter.

Rotation direction

cannot be changed and is standard from the motor to the impeller. A reverse flow fan can be ordered at extra cost (for non-ErP markets).

Clamps

is made of black plastic as standard and is located on the motor.

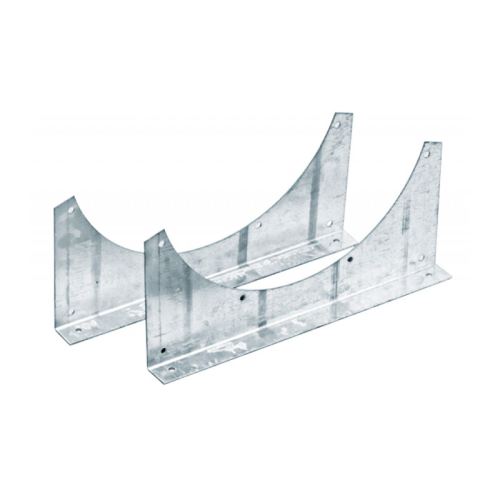

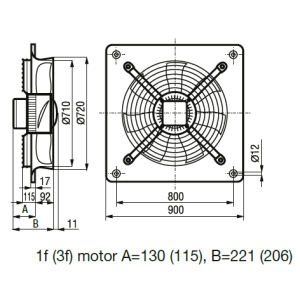

Mounting

is possible in any position of the motor axis. In the case of horizontal mounting, condensate drain holes must be opened in the rotor. The casing must not transmit mechanical stresses from the pipework. A flexible connection to the pipework must be used.

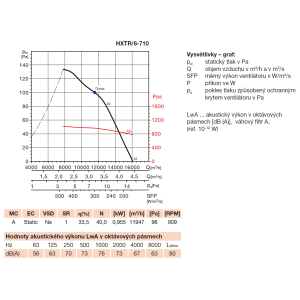

Noise

emitted by the fan is given in the tables, measurements are taken in the free field at a distance equal to three times the impeller diameter (but at least 1.5 m).

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email