General description of the system

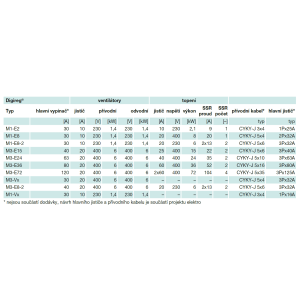

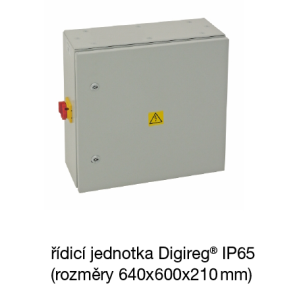

- The control system is housed in a compact steel-plated control cabinet equipped with a main switch, a digital controller on the PCB board, and safety and switching elements for the fans and the electric heater of the HVAC unit according to the power table.

- The cables pass through plastic grommets with locking on the left side of the cabinet.

Basic Features

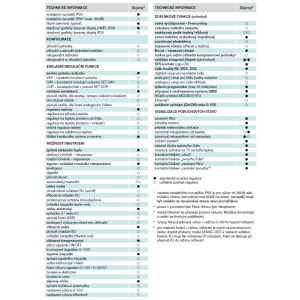

- Designed for air handling units in various designs with heating and cooling of air.

- Can be used for supply unit, supply and exhaust unit, heat recovery unit, hot air heating (recovery and circulation unit).

- Control and power part in one cabinet, outputs for connection of supply and exhaust fan, fans can be 3-phase or 1-phase, or with different speed controllers.

- Continuous regulation of supply air temperature.

- Monitoring of basic fault conditions of the air handling unit.

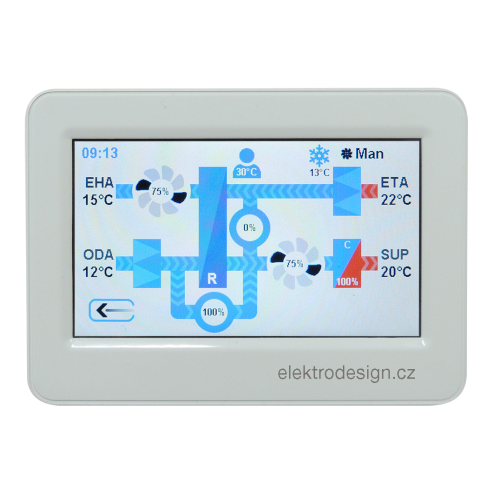

- Remote control with touch panel.

- Weekly time programmer.

- Dimensions and weights of air handling units:

M1-Vx, M3-Vx including lid, grommets and switch - 640x280x120 mm (w x h x d), weight approx. 8 kg

M1-E2 to M3-E36 including lid, grommets, heat sink and switch - 660x280x120 mm (w x h x d), weight 9.5-10 kg

M3-E72 including lid, grommets, heat sink and switch - 740x400x170 mm (w x h x d), weight approx. 15 kg (made to order)

Temperature control

Adjustable when commissioned according to the user's requirement

- The Digireg® controller is designed to control the output of the heater or cooler of the air handling unit to achieve the desired temperature. It can command direct cooling or heat pump. A 3-point output is provided for mixing valve actuator, direct power outputs SSR for electric heating or two 0-10 V/0-20 mA analog outputs for external heater controllers. Control of the heat pump or cooling unit by potential-free contacts.

- Control to constant supply air temperature - uses one temperature sensor in the supply pipe, supply air is heated or cooled to the desired set temperature within the minimum and maximum set temperature limits.

- Spatial temperature control (to constant room temperature). Cascade control is used with minimum and maximum supply air temperature limits. The main sensor is placed in the ventilated space, the supply air sensor is placed behind the heat exchangers in a location with sufficient air mixing. If the room temperature is higher than the setpoint, the controller will attempt to reduce the supply air temperature to the set minimum supply air temperature. If the room temperature drops below the set value, the controller will try to compensate for this by increasing the supply air temperature.

- The room temperature can be selected from the sensor on the exhaust, from a sensor in the controller, or from a separate sensor connected to the baseboard.

- The controller cools or heats according to the set parameters in automatic summer/winter mode according to the outside temperature and time dependencies. Fixed selection of summer/winter mode is also possible (in the service settings).

Exchangers

can be electric or water.

- The water heater is controlled by a three-point actuator. The output of the water heater is essentially unlimited (its output is determined by the size of the mixing node).

- The electric one is directly controlled by SSR or external triac 0-10 V switches. Depending on the design of the switchgear, it can be switched and fused up to 72 kW.

- Water chiller is controlled by an analogue 0-10 V servo drive.

- Direct chiller - on/off control of a condensing chiller or inverter condensing chiller with an analogue 0-10 V signal.

- Control of the condensing unit as a heat pump for heating/cooling.

- Control of the recuperator bypass damper with an analog or three-point servo drive.

- Use of the recuperator analog bypass to control cooling or heating.

- Possibility of controlling a 0-10 V or on/off rotary recuperator.

- Use of independent analog output of proportional controller for mixing damper to control to constant or differential temperature, dehumidification control.

- Control of cooling and heating pump.

- Control of electric heating safety contactor.

- Control of gas heater operation.

- Command of air or liquid ground collector with temperature and time dependencies. Outdoor temperature, start-up time and collector capacity over a 24-hour period.

- Triggering of preheat operation for heat recovery units according to actual demand.

- Automatic summer and winter operation recognition or fixed mode selection.

- Control of bivalent electric or liquid source for heat pump.

- Humidity control and trailing temperature control (pool ventilation)

- Separate outputs for contact signalling of operation and faults (filters, sensors, central fault).

- Optional control from three locations.

- Programmable input for remote contact interlock.

Configuration

The following device configurations can be controlled.

- Supply unit control

- Supply and extract unit control

- Recovery unit control:

- Analog/digital bypass in plate/rotary design

- Bypass on supply or extract

- Superheat control

- Recovery unit and heating unit control (hot air heating)

Control options

- Control for supply temperature

- Control for space temperature - sensor in the controller

- Control for space temperature - separate space sensor

- Control for extract temperature

- Drag temperature control - for pool ventilation from temperature water

- Monitoring of duct minimum and maximum

- PID parameter selection

- Selection of recuperation unit functions

- recuperation enabled/disabled

- equal pressure ventilation

- free cooling by outside air

- ventilation only

Remote control

- The standard Digireg® CP-TFT touchscreen controller on RS485 bus is used for operation. If more comfortable control is required, one or two Digireg® CP-TFT controllers with RS485 ModBus communication can be connected

- Parameter change is user-friendly by touching the required data without the need for complicated searches in subdirectories

- Communication via RS485 data line

- Possibility of communication with the higher-level system (building control room), communication protocol via RS485 bus

Fan motors

by type of electric motor

Single phase motors:

- Control of EC, FM motors by 0-10 V outputs

- Direct switching of two-turn motors up to 1.4 kW

- Control by REE6 triac controller

- Motor protection

- Monitoring of motor safety or signal contacts

Three-phase motors:

- Control of EC, FM motors with 0-10 V outputs

- Possibility of controlling direct switching of two-turn motors

- Motor protection

- Monitoring of safety or signal contacts of motors

- Switching with Digireg® ST+

Heaters

by heater type

Electric heating

- Single section / dual section control

- Control of rod / wire heat exchangers

- Continuous power control by SSR, ON/OFF heating switching capability

- Emergency thermostat status monitoring

- Heater protection by power series

- Heater safety contactor

- 0-10 V and 0-20 mA output for external heaters (for sections 1 and 2)

Heat water heating

- Three-point mixing node control

- Two-stage frost protection

- Backflow/PMO water temperature monitoring

- Continuous start-up of water heat exchanger

- Heater pump switching

Gas heating

Cooling

by media type

Compressor

- Adjustable compressor operating parameters

- Minimum compressor run time monitoring

- Monitoring the number of switch ons per hour

- Potential-free compressor switching command

- Cooling and heating power control

- 0-10 V analog power control

Cold-water cooling

- Continuous control via mixing node

- Cooling pump switching

Heat pump

Heating/cooling system

- Use for both heating and cooling

- 0-10 V analog power control (0 V = 0% power, 10 V = 100% of power in both cooling and heating mode)

- Bivalent electric or water heat source control

- Bivalence from two temperature thresholds for SSR (Solid State Relay) electric reheat

- Bivalence from two temperature thresholds for ESU analog outputs (this is the ratio of the outdoor temperature and the desired output temperature value with a time constant)

Heat pump defrost function

To implement the defrost mode functions, the DHVAC-ODT add-on module must be added to the processor board and the optional functions must be set. The AHU or AHU box must be equipped with a DI output which is activated when the AHU is switched to defrost mode. The response of the supply fan, mixing/circulation damper and the start of the auxiliary/balancing heater can be set, depending on the unit design.

Recuperation

By exchanger type

- Plate recuperator

- Plate recuperator with bypass

- Rotary regenerative exchanger

- 0-10V or on/off control

- Bypass is recommended to be controlled by analog actuator, three point actuator can also be used

Free cooling - freecooling

- Automatic start of cooling according to the temperature difference between indoor and outdoor area

- Time programming of cooling

Ground collector/preheating

- Control of liquid or air ground heat exchanger or preheater

- Setting of usage time / regeneration time

- Setting of temperature limits for summer / winter

Mixing damper

- Can be used to mix air or as an additional independent proportional controller

- Absolute / Relative setpoint temperature setting

- Steepness of control

- Hygienic minimum setting

- Control to absolute temperature or temperature difference, Manual

- Selection of feedback or differential sensor from already installed sensors

- Special damper mode for circulation heating/cooling

- Possibility to control damper position from analog input for humidity and ventilation power

- Possibility to control humidity by inverse function

Function Fire

- Setting of the unit's fire behavior (set to desired output, off/10-100%). Only functional when the HVAC is running! Deactivation of this mode requires a special reset mode.

Boost function (ventilation - ext. control)

- Setting the activation delay time

- Setting the required motor power

- Setting the possible temperature increase

- Setting the run time - switching to normal program mode

- Possibility to activate pool ventilation

Humidity

Digital hygrostat control

- Digital input for hygrostat control

- Possibility to configure the input as a remote interlock with potential-free contact

- Setting of power and timeout time

- Possibility to configure in service mode as an interlock input

Analog control by sensor rel. humidity

- Setting the desired relative humidity in percent

- Possibility to set the min. fan speed

- Analog input for controlling the fan power (PI control)

Air quality (CO2, SQA)

- Digital input for control by CO2 or SQA

- Power and run time settings

Analog control by air quality sensor

- Setting the desired air quality in percentage (CO2)

- Analog input for fan power control (PI control)

Unit timing

- Four possible presets for temperature, function and fan speed with the possibility of programming in 5 min intervals and combinations during the day (16 changes/day possible - i.e. 8 blocks).

- Weekly programmer

- Copying of daily programs

- Time programs are stored in the memory of the Digireg® CP-TFT

Connection to the parent system

.Not standard with the controller.

- Connection to the control room is possible through the company's software implementation either by direct communication from one of the two RS485 ModBus or via Ethernet

- ModBus RTU communication protocol for direct on-demand connection

- For Ethernet communication, a converter must be added according to the type of connection required

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email