Information

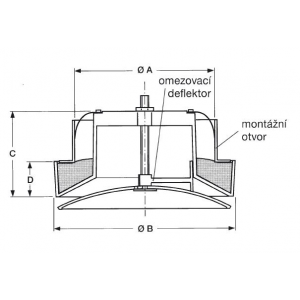

Plastic plate air inlet valves have an easily adjustable center element for flow control. The valve is equipped with a pressure measuring port. At the same time, the plate valve can be equipped with an adjustable deflector to restrict the supply air flow into the space at 180˚. The plate valve is provided with a sealing tape for sealing in the mounting ring. Plastic valves can be cleaned with mild solutions of non-aggressive detergents. VST valves are made of polypropylene, colour white. They resist some diluted chemicals. The highly advantageous aerodynamic shape reduces valve noise and significantly reduces the risk of crosstalk.

- for air supply suitable for homes, offices, etc.

- good adjustment parameters

- low noise level

- quick and easy installation

- easy measurement of air flow

- low pressure drop

- ambient temperature up to 100 ˚C

- resistance to some chemicals

- deflector option

Installation:

The valves are inserted by flat springs into the VLZ brickwork, which allows the valve to be fixed into a ceiling structure, wall or pipe. The plate valve is inserted from one side of the brickwork, a flexible flex head is inserted from the other side and the joint is fixed with steel or nylon clamping tape. The wall can also be fixed in a circular pipe. For pipes Ø 150 and Ø 160, the appropriate VLZ brickwork and plate valve Ø 160 are always used.

Measurement and control:

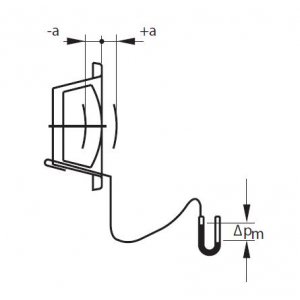

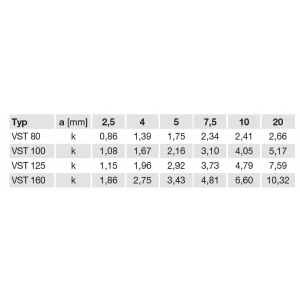

The air flow is controlled by turning the central disc, which changes the valve opening "a" (mm). Air flow measurement is performed as a pressure differential measurement using a measuring tube. See diagrams for further details. The dependence of the flow rate and pressure drop on the valve opening "a" is expressed by the relationship:

q = k √Δpm (l/s), (Pa)

In the diagrams, n = number of revolutions of the disc and a = valve opening (mm). The range is given for a maximum flow velocity of v = 0.2 m/s.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email