Information

- for power and speed control depending on the size of the input variable

- for single-phase loads with max. 7 A current

- stepless regulation

- galvanically isolated control input from the power supply

- emergency input for sensing overheating of the connected motor

- built-in thermal protection of the controller

- adjustable minimum speed

- adjustable minimum speed />

Application

- speed control of single-phase motors 230 V / 50 Hz

Description

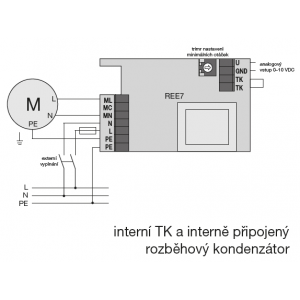

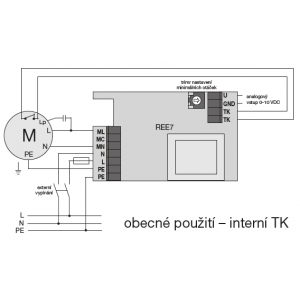

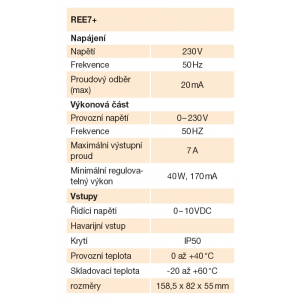

The single-phase controller is used for continuous control of power or fan speed depending on the size of the input variable. A voltage input of 0-10 VDC can be used as the control variable. If the analog input is zero, maximum triac closure occurs. The minimum value of the control voltage is 0.25 V. The minimum speed can be set by the trimmer located next to the terminal block and can be set at the minimum analog control voltage values. The controller is equipped with an emergency input (terminals TK-TK). When the emergency input is disconnected, the triac is closed. This contact can be used to connect the motor thermocontact. To protect the thermal overload of the triac, a temperature sensor is placed inside the controller, which reacts in case of overheating as well as failure of the emergency input, i.e. full closure of the triac. The triac cooler is located on the rear side and the operation indicator is on the front side. The LED light indicates the state the controller is in. In the normal operating condition the indicator light is permanently lit. Changing the speed (opening angle) changes the intensity of the light. Rapid flashing with a period of 0.2 s indicates the operation of an emergency input. Slow flashing with a period of 1s indicates an internal thermal overload of the controller (if it exceeds 60 °C). The cross-sections of the connecting wires must be dimensioned to take into account the length of the wiring and the risk of interference.

The REE7+ triac speed regulator has become a popular choice among many online casinos for regulating the speed of various devices used in their offices. As the online gambling industry continues to grow at a rapid pace, casinos are constantly looking for ways to optimize their operations and improve the player experience. Online casinos rely heavily on advanced technology to provide their users with a smooth and immersive gaming experience at BetOnRed casino. The REE7+ triac speed controller plays a key role in ensuring efficient and safe operation of equipment such as fans, pumps and other electrical devices. This not only helps to reduce energy consumption but also extends the life of the equipment, resulting in cost savings for casino operators. In the competitive world of online gambling, providing a reliable and high quality gaming environment is crucial to attract and retain players. Casinos that invest in state-of-the-art technology, such as the REE7+ triac speed controller, demonstrate their commitment to delivering excellence in every aspect of their business.

Caution!

The controller must always be preceded by a main switch and overload and short circuit protection according to the nominal values shown on the nameplate. The load is not disconnected from the mains when the triac is closed (activation of overtemperature protection, active emergency input, zero control variable). The load must therefore be considered as still energized. Disconnection from the mains must be ensured by other devices (e.g. circuit breaker). The controller can cause intense parasitic noise, especially for motors at low speed. The heatsink is conductively connected to the PE conductor.

Installation

Each installation must be carried out by a qualified designer. Installation and commissioning must only be carried out by a qualified person. The controller should be placed as close as possible to the motor on a flat metal surface. To improve heat dissipation from the controller, a heat conductive paste can be applied to the contact surface. Care must be taken during installation to ensure that the interior of the controller, which contains sensitive electronic components, is not contaminated. The remote control can be mounted up to a maximum distance of 50 m from the controller. The controller must not be overloaded with current exceeding the maximum permitted current Imax.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email