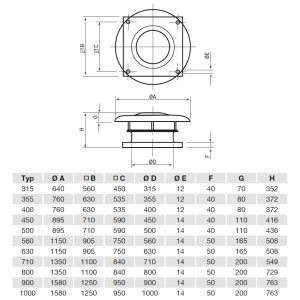

Cabinet

is designed for horizontal air exhaust. The fan base is made of galvanized steel sheet, the brackets, grille and screws are also electroplated. The fan shroud is made of Al sheet metal. The fan motor is mounted in the air stream.

Running wheel

The fan is axial. For sizes 315 to 400 it is made of glass fibre reinforced thermoplastic, for sizes 450 to 1000 the hub is made of Al alloy and the blades are plastic. The impeller is statically and dynamically balanced.

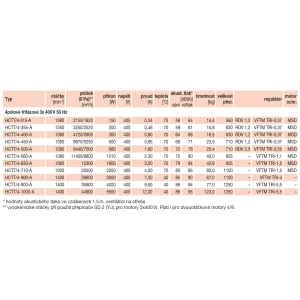

Motor

is asynchronous with shorted resistance armature, stator with cooling fins, black epoxy lacquer finish. The motors are fitted with a thermal fuse as standard (except sizes 800 to 1000). The windings are tropicalised with Class F insulation and have a permanent operating temperature of -40 to +70˚C, IP65 protection (sizes 800 to 1000 have an operating temperature of -30 to +40˚C and IP55 protection). Ball bearings with grease packing for life.

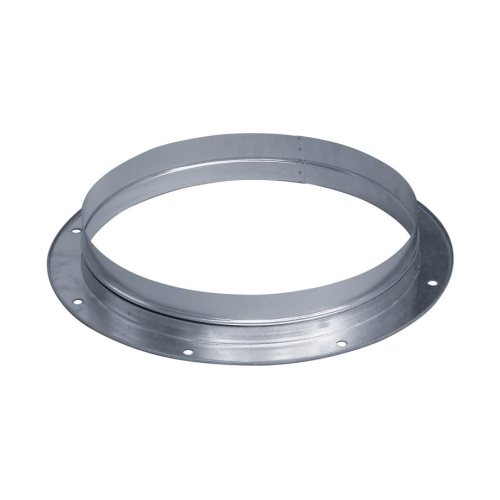

Clamps

It is made of black plastic as standard, on single phase fans it also contains a start-up capacitor. The protection is IP65. The terminal block is located on the fan housing.

Speed control

is done by changing the voltage or frequency (see table for controller). Motors marked 400 V can be switched to reduce the speed by switch SD 2. (Alternatively, the supplied 230/400 V motors cannot be regulated in this way and can only be operated in Y connection).

Rotation direction

is for inlet or outlet in the sense of the arrow on the fan housing. If the direction is reversed, the order of the phases must be reversed.

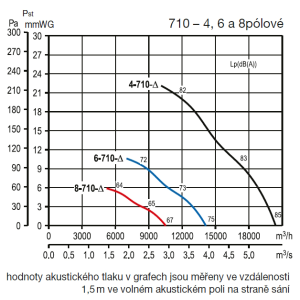

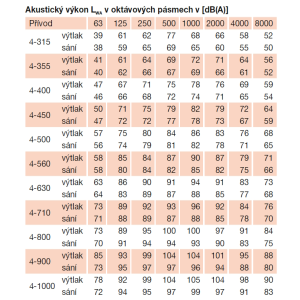

Noise

emitted by the fan is given in the tables as sound pressure values at a distance of 1.5 m, measured in the free sound field.

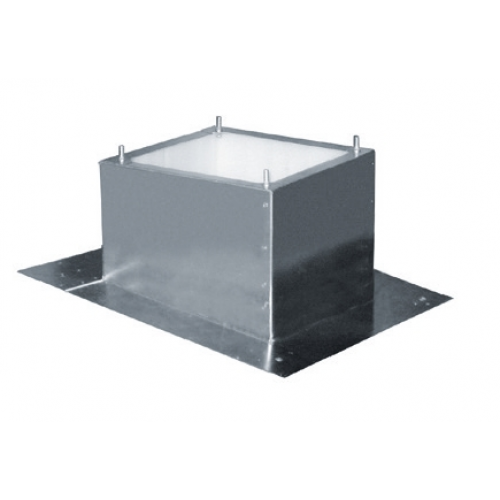

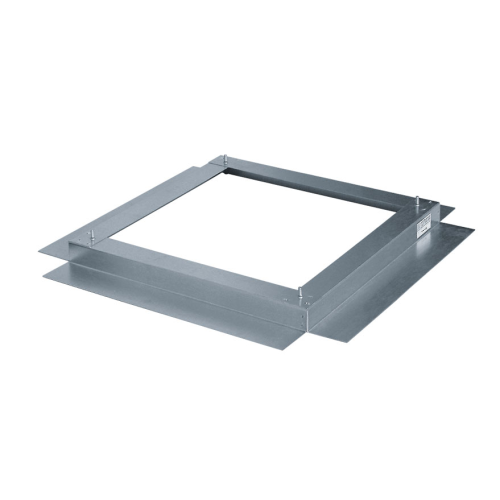

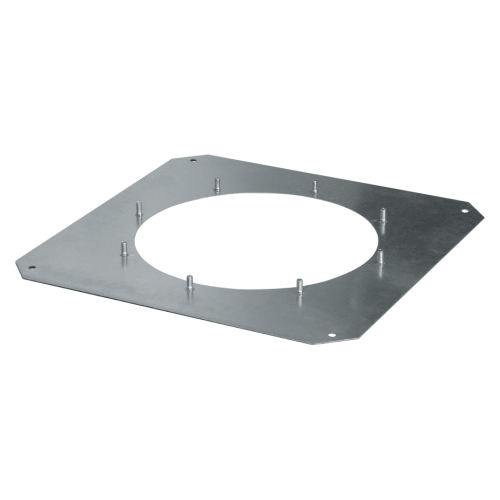

Mounting

The fan is mounted horizontally by means of accessories (with the motor axis vertical).

Instructions

The fans are suitable for ventilation of industrial halls, plants, swimming pools and warehouses.

Share on Facebook

Share on Facebook Tweet

Tweet Send email

Send email